When it comes to transporting and storing bulk materials, Flexible Intermediate Bulk Containers (FIBCs), also known as bulk bags, big bags, or super sacks, are a popular choice in various industries. These bags come in different types, each tailored for specific applications based on factors such as safety, handling requirements, and the materials they will be used to transport. Let’s delve into the four main types of FIBC bags: Types A, B, C, and D. Characteristics: – Made from standard polypropylene fabric. – No measures to prevent static electricity. – Suitable for non-flammable materials. Applications: Type B FIBC bags are similar to Type A but have a slightly different construction to provide limited protection against static electricity. They are made from non-conductive polypropylene fabric but lack any measures to safely dissipate static charges. Characteristics: – Constructed from non-conductive polypropylene fabric. – No measures for static dissipation. – Offer limited protection against static electricity. Applications: Type C FIBC bags, also known as Conductive FIBCs, are designed to safely dissipate static electricity to prevent the risk of sparks. They are made from non-conductive polypropylene fabric interwoven with conductive threads or have a grid of conductive yarns that ground the bag. Characteristics: – Made from non-conductive fabric with interwoven conductive threads. – Designed to safely dissipate static electricity. – Groundable to prevent sparks and fires. Applications: Type D FIBC bags, also referred to as Antistatic FIBCs, are constructed from antistatic fabric that prevents the occurrence of incendiary discharges. Unlike Type C bags, Type D bags do not require grounding. They are considered a safer option for transporting and storing flammable powders and materials. Characteristics: – Made from antistatic fabric. – Prevents incendiary discharges without grounding. – Suitable for flammable materials. Applications: When choosing the right FIBC bulk bag for your operations, it’s important to go beyond size and capacity. Several additional factors play a crucial role in ensuring safety, efficiency, and compatibility with your materials and processes. Here are key considerations to keep in mind: Taking these additional factors into account alongside standard FIBC bulk bag specifications will help ensure you select a container that aligns perfectly with your operational, safety, and regulatory requirements. Understanding the different types of FIBC bags is crucial for selecting the right packaging solution for your specific needs. Whether you are dealing with non-hazardous materials, flammable powders, or combustible dust, there is an FIBC type designed to ensure safety and efficiency in handling and transportation. Always consult with experts in bulk packaging to determine the most suitable FIBC type for your application.Types Of FIBC Bags: A, B, C & D FIBC Types Explained

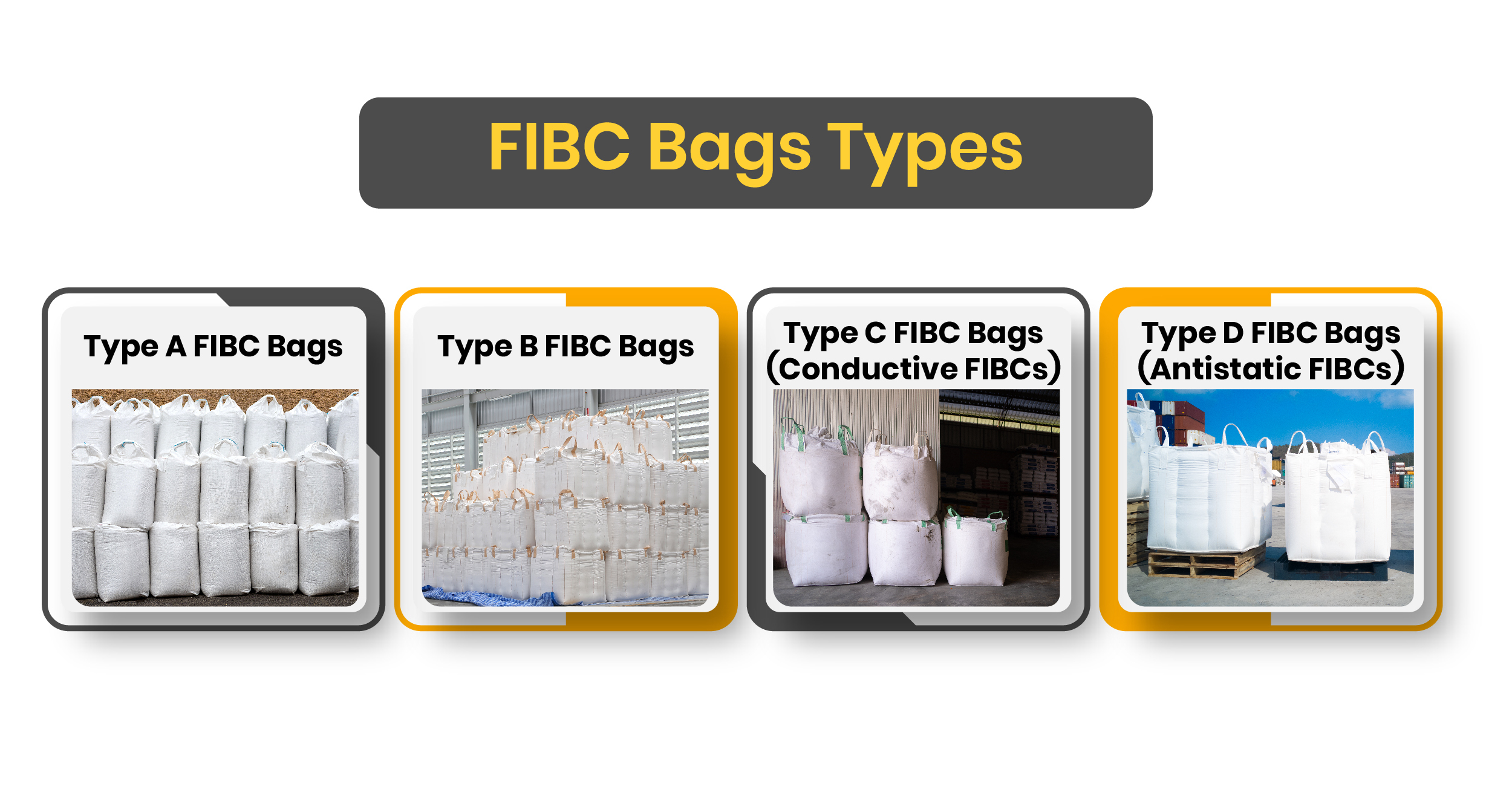

FIBC Bags Types:

Type A FIBC Bags

Type A FIBC Bags Type A FIBC bags are the most basic form of bulk bags. They are constructed from woven polypropylene fabric without any additional measures to prevent the occurrence of static electricity. These bags offer no protection against the buildup of static charges and are designed for use with non-flammable products.

Type A FIBC bags are the most basic form of bulk bags. They are constructed from woven polypropylene fabric without any additional measures to prevent the occurrence of static electricity. These bags offer no protection against the buildup of static charges and are designed for use with non-flammable products.Type B FIBC Bags

Type C FIBC Bags (Conductive FIBCs)

Type D FIBC Bags (Antistatic FIBCs)

Additional Factors to Consider When Selecting a Flexible Bulk Container

The top construction of an FIBC bag affects how it’s filled and sealed. Common top styles include duffle tops, spout tops, open tops, and flap tops—each suited to different filling processes and material types. Choosing the right top style can enhance operational ease and reduce product loss during handling.

FIBC bags are available in coated (laminated) or uncoated forms. Coated bags offer additional protection against moisture and fine particle leakage, making them ideal for powdered or hygroscopic materials. Uncoated bags are more breathable and are typically used for coarse or dry materials that don’t require moisture barriers.

Lift loops are critical for safe and efficient transportation of FIBCs. The number, position, and strength of the loops—such as standard corner loops, cross-corner loops, or sleeve lifts—should align with your handling equipment (like forklifts or cranes) and the weight of the product being carried.

If your material is flammable, or if your working environment involves explosive dust or vapors, electrostatic safety becomes essential. FIBCs are categorized into Types A, B, C, and D based on their static protection properties. Type C and D bags are specifically designed to mitigate electrostatic discharge, ensuring safety in hazardous conditions.Conclusion

FAQs

FIBC bags are made from woven polypropylene, a strong and lightweight thermoplastic polymer.

Standard FIBC bags are not waterproof, but they can be made moisture-resistant with inner liners or lamination.

FIBC bags are manufactured by weaving polypropylene tapes into fabric, which is then cut, sewn, and assembled into various bag styles.

Standard FIBC bags typically measure around 35x35x50 inches, but sizes can be customized based on specific needs.

Types Of FIBC Bags: A, B, C & D FIBC Types Explained