Conductive FIBC’s should be used to avoid accidents caused by any type of electrostatic discharges which may occur during the filling discharge procedure.

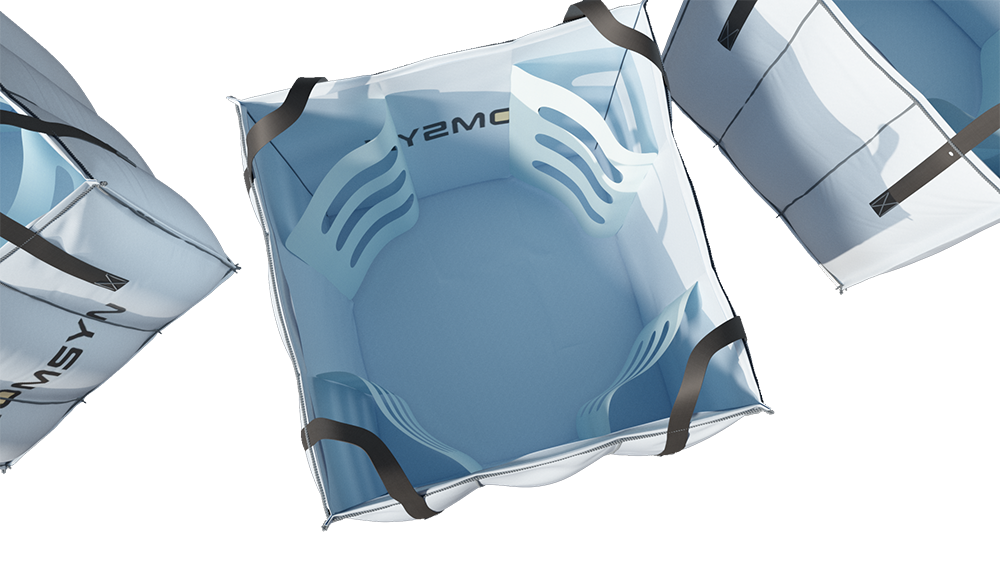

Type C Fibcs normally made of non-conductive fabric with interwoven conductive threads.

Those conductive threads must be interconnected with less than 1.0 x 108 ohm and must be grounded during filling and emptying operations. Some Type C FIBCs have interconnected conductive loops to enable grounding via a (grounded) hoist system. When grounded properly there is no risk of incendive discharges.

The inner or outer surfaces of the FIBC may have a thin coating. In this case the breakdown voltage to the conductive threads must not exceed 6 kV to avoid propagating brush discharges.

Thus, Type C FIBCs can be used in an environment with combustible dusts and/or explosive gases. There is no risk using these FIBCs in hazardous areas zones 1, 2, 21, 22, providing they are properly grounded