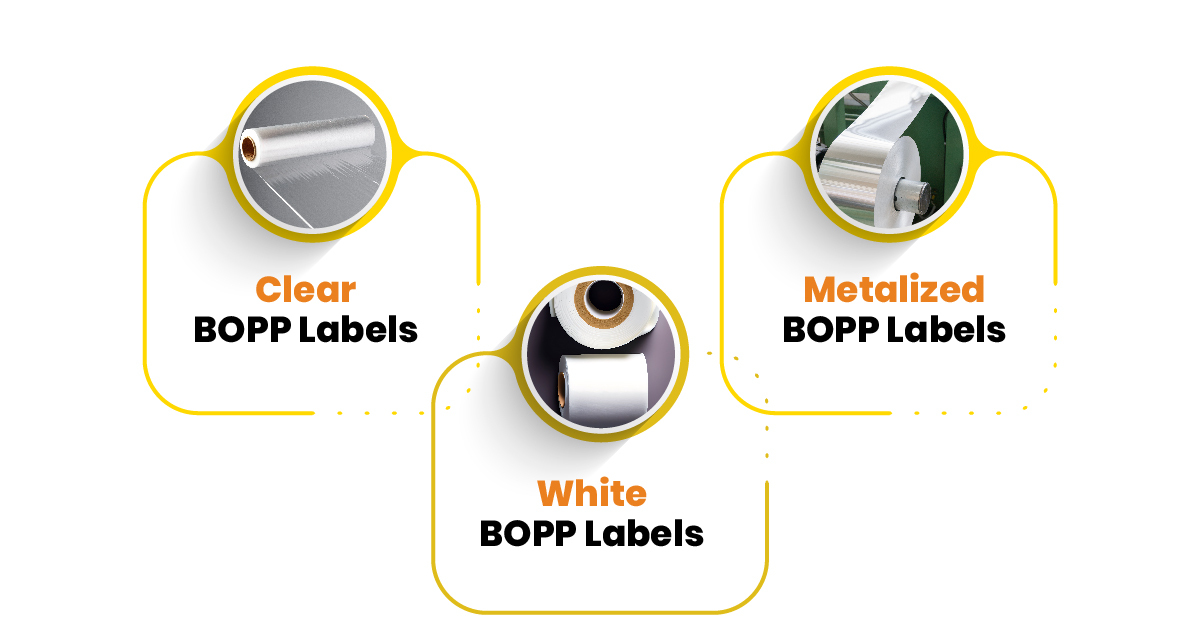

BOPP stands for Biaxially Oriented Polypropylene, a type of plastic material renowned for its durability and versatility. The term “biaxially oriented” refers to the process by which the polypropylene is stretched in both the machine direction and across the machine direction. This biaxial orientation enhances the film’s strength, clarity, and barrier properties, making it an excellent choice for labels and laminated pp woven bags. The manufacturing process of BOPP involves melting polypropylene pellets and then extruding them into a thin film. This film is then stretched in two directions, enhancing its mechanical and optical properties. The result is a robust, transparent, and resistant material, making it an excellent choice for a variety of packaging applications, including BOPP bags and printed pp woven bags. BOPP labels come in several types, each with its unique characteristics and uses. The three main types are clear, white, and metalized BOPP labels. Uses: Ideal for products where a “no-label” look is desired, such as on clear bottles or packaging. They are perfect for products where visual appeal is crucial, such as cosmetics, beverages, and high-end consumer goods. Benefits: Provides a high-quality, professional appearance that makes the product’s branding and contents highly visible. These labels are also resistant to moisture and oils, maintaining their integrity even in challenging conditions. This durability ensures that the product remains appealing and informative to consumers, ultimately enhancing the overall customer experience. Uses: They are commonly used for products that require a solid, opaque background for text and graphics, such as food containers and cosmetics, making them ideal for products that require high-contrast printing. Benefits: Offers excellent printability and vibrant color reproduction, ensuring that the labels are easy to read and visually appealing. These labels are widely used in the food and beverage industry, pharmaceuticals, and household products. Uses: Often used for premium products, promotional items, and special promotions, it provides a shiny, metallic finish that stands out. Benefits: It adds a luxurious touch of elegance and sophistication to any product packaging, making it ideal for products that need to convey a high-end image. The metalized finish not only enhances the visual appeal but also provides additional barrier properties against light and oxygen, helping to preserve the product’s quality. BOPP labels are highly regarded for their exceptional properties, making them ideal for a wide range of labeling needs. Here are some of the reasons why BOPP is the material of choice for many PP woven sack bag manufacturers: BOPP labels are highly durable and can withstand rough handling, making them suitable for products that are frequently transported or handled. They resist tearing, scratching, and abrasion, ensuring that the labels remain intact and legible throughout the product’s lifecycle. BOPP labels are waterproof and resistant to oils and chemicals, which makes them perfect for products that are exposed to moisture or harsh conditions. Whether it’s a bottle of shampoo in the shower or a container of motor oil in the garage, BOPP labels maintain their adhesion and appearance. The clarity of BOPP film allows for high-quality printing, resulting in sharp, vibrant images and text. This makes BOPP bags ideal for branding and conveying critical information. The smooth surface of BOPP film also ensures excellent ink adhesion, preventing smudging or fading. BOPP labels are recyclable, contributing to a more sustainable packaging solution. Many BOPP films are made with environmentally friendly processes, and efforts are continuously being made to enhance their eco-friendliness. BOPP labels are versatile and can be used in a wide range of industries. Here are some common applications: In the food and beverage industry, BOPP labels are used on a variety of products, from bottles and jars to pouches and cans. Their resistance to moisture and oils makes them ideal for labeling items like sauces, dressings, and beverages. Household products, such as cleaning supplies and detergents, benefit from BOPP labels due to their resistance to chemicals and moisture. These labels ensure that product information stays visible even in harsh conditions. BOPP bags are an excellent choice for packaging fertilizers due to their durability and moisture resistance. These bags provide a strong barrier against external elements, ensuring fertilizers remain dry and effective during storage and an ability to print high-quality graphics transportation so that manufacturers can enhance brand visibility and convey essential product information. When packaging pet and cattle foods, BOPP bags offer the perfect blend of strength and flexibility. These bags can withstand rough handling and heavy weights, making them ideal for large quantities of feed. Additionally, BOPP bags maintain the freshness of the food by protecting it from moisture and contamination, ensuring that the nutritional value remains intact for your animals. BOPP bags are not only functional but also serve as an effective promotional tool. Their glossy finish and high-quality printability allow brands to create eye-catching designs that stand out on shelves. Whether for giveaways, events, or limited-edition packaging, BOPP bags can be customized to enhance brand recognition and appeal to consumers, making them a versatile choice for promotional use. BOPP labels offer numerous advantages, making them a preferred choice for many PP woven sack bag manufacturers. Here are some key benefits: BOPP labels are recyclable and often produced with environmental friendly processes. This contributes to reducing the environmental impact of packaging and supports sustainable practices. By choosing BOPP labels for your packaging needs, you ensure durability, clarity, and sustainability, making them an excellent choice for a variety of applications, including laminated pp woven bags and printed pp woven bags. BOPP labels offer cost-effective solutions due to their durability and resistance to damage. This reduces the need for label replacements and ensures that products maintain their branded appearance for longer periods of time. BOPP labels provide excellent print quality, durability, and resistance to various environmental factors. They are easy to apply and can be used on a wide range of products, making them a practical choice for many industries. BOPP labels are a versatile and reliable option for a wide range of packaging needs. Their durability, resistance to water, oil, and chemicals, and excellent print quality make them an ideal choice for industries ranging from food and beverage to personal care and pharmaceuticals. When considering labeling options, BOPP labels offer numerous benefits that can enhance both the appearance and functionality of your packaging. 1. What are BOPP labels made of? BOPP labels are made of biaxially oriented polypropylene, a type of plastic that is stretched in both directions for enhanced strength and clarity. 2. How durable are BOPP labels compared to other types? BOPP labels are highly durable, offering superior resistance to tearing, scratching, and abrasion, making them more durable than many other types of labels. 3. Can BOPP labels be used on all types of packaging? Yes, BOPP labels are versatile and can be used on various packaging types, including bottles, jars, boxes, cans, and bags. 4. Are BOPP labels waterproof? Yes, BOPP labels are waterproof and also resistant to oils and chemicals, making them suitable for products exposed to moisture or harsh conditions. 5. What industries benefit most from using BOPP labels? Industries such as food and beverage, cosmetics and personal care, pharmaceuticals, and household products benefit significantly from using BOPP labels. 6. How are BOPP labels printed? BOPP labels can be printed using various methods, including flexographic, digital, and offset printing, allowing for high-quality, vibrant prints. 7. Are there any environmental benefits to using BOPP labels? Yes, BOPP is recyclable, and its durability reduces the need for frequent replacements, contributing to less waste. 8. What is the difference between clear and white BOPP labels? Clear BOPP labels provide a “no-label” look, making the product’s contents visible, while white BOPP labels offer a solid background for text and graphics, enhancing readability. 9. How do I choose the right type of BOPP label for my product? Consider your product’s packaging, desired appearance, and any specific environmental or chemical exposures when choosing the type of BOPP label. 10. Can BOPP labels be recycled? Yes, BOPP labels are recyclable, contributing to sustainable packaging practices.Decoding BOPP Labels: Everything You Need to Know Before Choosing

Labels are the unsung heroes of the packaging world. They communicate essential information, attract customers, and give products a distinct identity. One label material that stands out in the industry for its versatility and durability is BOPP. In this blog, we will decode everything you need to know about BOPP labels, helping you make an informed choice for your packaging needs.What is BOPP?

What Types of BOPP Labels Are Available?

Clear BOPP Labels

White BOPP Labels

Metalized BOPP Labels

Why Use BOPP for Your Labels?

Durability

Resistance to Water, Oil, and Chemicals

Clarity and Print Quality

Environmental Benefits

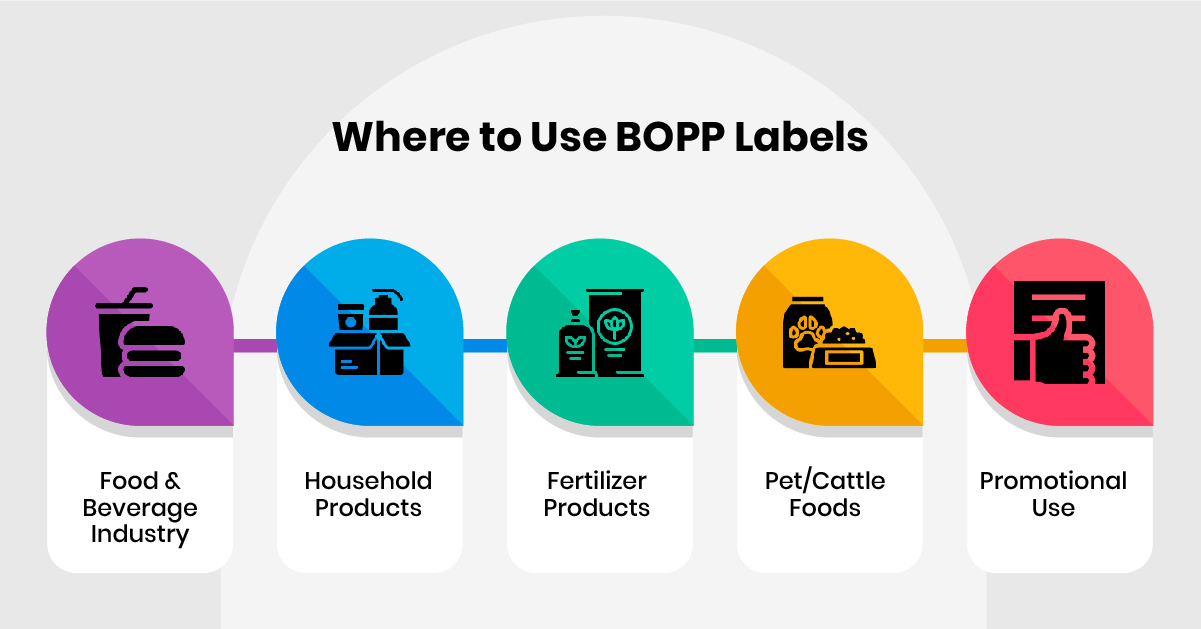

Where to Use BOPP Labels

Food and Beverage Industry

Household Products

Fertilizer Products

Pet/Cattle Foods

Promotional Use

Benefits of BOPP Labels

Environmental Benefits

Economic Benefits

Practical Benefits

Conclusion

FAQs

- About Us

- Products

- Markets Served

-

- Investor Relation

- Board Of Directors

- Committees Of Board

- Corporate Governance

- Financials

- Annual Report

- Key Managerial Positions

- Shareholding Pattern

- Notices

- Policies Programme

- Announcements

- Statement of Investor Complaints

- Unpaid & Unclaimed Dividend

- Prospectus

- Investors Contact

- Subsidiary Financials

- IEPF

- Preferential Issue – 2024

- MOA & AOA

- Integrated Filing

- Sustainability

- Contact Us

- TechTex

- Brochure